Contents Menu

GEARED MOTOR SF-PRP 80M~225S FOOT TYPE

GEARED MOTOR SF-PRP 80M~225S FOOT TYPE Series (Outdoor Waterproof Motor) P9

Can be sued safety outdoors, even under weather conditions such as rain,wind,snow,etc.

“Super Line Premium Series SF-PRP” demonstrates the full potential of Mitsubishi high-efficiency technology. While maintaining the ease of use of general-purpose motors. With proprietary steel frame technology, Mitsubishi Electric will continue to develop and sell products that comply with global high efficiency regulations.

SF-PRP 80M~225S FOOT TYPE

TOTALLY ENCLOSED FAN-COOLED TYPE, IP55 DEGREES OF PROTECTION (Outdoor Dust & Water jet proof Motor)

Features

Dust & Water jet proof performance (IP55 Degrees of protection)

Passed the dust and the water spray test for compliance with JIS C 4034-5, so it can be used with confidence in locations exposed to large quantities of water.

Construction

The main parts of the motor are the same as SF-PR, but in order to provide stable operation under even more severe conditions than those of the outdoor type, special consideration is given to the following.

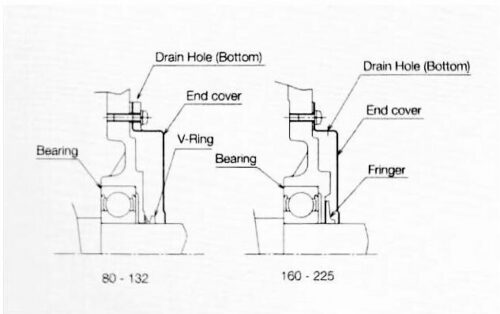

- Shaft through part

Both the load side and the anti-load side are provided with a fringer or V-ring that rotate together with the shaft so as to prevent water leaking into the motor.

In addition, end covers are mounted on the load side and anti-load side to further improve the dust & water jet proofing.

* The vertical flange type motor has a fringer or V-ring mounted on the

anti-load side, while the horizontal flange type motor has a fringer or V-ring and end cover mounted on the anti-load side. Note that the shaft through part does not have a waterproof structure since the load side of the vertical flange and horizontal flange type motors is incorporated into the mating machine.

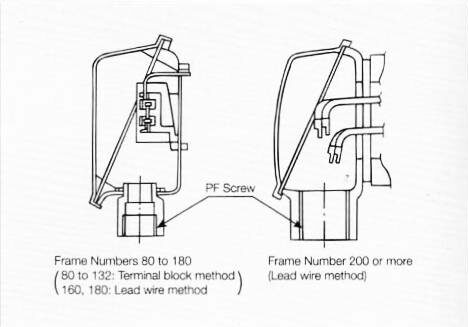

- Terminal box

Load side shaft through structure on outdoor dust & water jet proof motor

- Mating part

- Installation method

- Coating

Terminal box detailed view

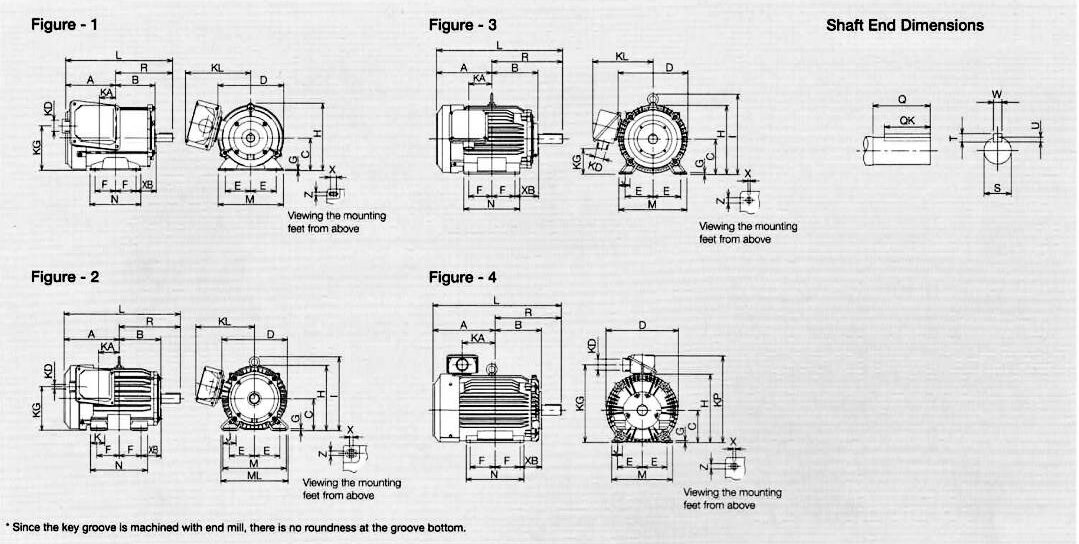

Dimensoin Table

| Frame Number |

Thermal Class |

Output (kW) |

Figure Number |

Dimensions (mm) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Motors | ||||||||||||||||||

| 4 Pole | A | B | C* | D | E | F | G | H | I | J | K | KA | KD | KG | KL(KL) | |||

| 80M | 120 (E) |

0.75 | 1 | 122 | 97 | 80 | 162 | 62.5 | 50 | 3.2 | 166 | - | - | - | 39.5 | PF 3/4 | 109 | 168 |

| 90L | 1.5 | 143 | 116.5 | 90 | 184 | 70 | 62.5 | 4 | 191 | - | - | - | 53 | PF 3/4 | 123 | 173 | ||

| 100L | 2.2 | 2 | 173 | 132 | 100 | 207 | 80 | 70 | 6.5 | 203.5 | 230 | 40 | 45 | 65 | PF 3/4 | 136 | 185 | |

| 112M | 3.7 | 181 | 139 | 112 | 228 | 95 | 70 | 6.5 | 226 | 253 | 40 | 45 | 69 | PF 3/4 | 151 | 196 | ||

| 132S | 130 (B) |

5.5 | 211.5 | 158 | 132 | 266 | 108 | 70 | 6.5 | 265 | 288 | 40 | 45 | 75 | PF 1 | 177 | 223 | |

| 132M | 7.5 | 230.5 | 177 | 132 | 266 | 108 | 89 | 6.5 | 265 | 288 | 40 | 45 | 94 | PF 1 | 177 | 223 | ||

| 160M | 11 | 3 | 252 | 209 | 160 | 318 | 127 | 105 | 8 | 316 | 367 | 50 | - | 105 | PF 1 1/4 | 116 | 274 | |

| 160L | 15 | 274 | 231 | 160 | 318 | 127 | 127 | 8 | 316 | 367 | 50 | - | 17 | PF 1 1/4 | 116 | 274 | ||

| 180M | 18.5,22 | 292.5 | 237.5 | 180 | 363 | 139.5 | 120.5 | 8 | 359 | 410 | 50 | - | 127 | PF 1 1/2 | 140 | 296 | ||

| 180LD | 155 (F) |

30 | 4 | 349.5 | 258.5 | 180 | 406 | 139.5 | 139.5 | 11 | 381 | - | 58 | - | 184 | PF 2 | 432 | (487) |

| 200LD | 37,45 | 355 | 282 | 200 | 446 | 159 | 152.5 | 11 | 421 | - | 64 | - | 145 | PF 2 | 487 | (567) | ||

| 225S | 55 | 425 | 282 | 225 | 446 | 178 | 143 | 11 | 446 | - | 70 | - | 205 | PF 2 1/2 | 512 | (592) | ||

| Frame Number |

Dimension (mm) | Bearing Number | Approximate Unloaded Mass(kg) |

||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Motors | Shaft End | ||||||||||||||||||

| L | M | ML | N | X | XB | Z | Q | QK | R | S | T | U | W | Load Side | Anti-Load Side | 4 Poles | |||

| 80M | 262 | 160 | - | 125 | 15 | 50 | 9 | 40 | 32 | 140 | 19j6 | 6 | 3.5 | 6 | 6204ZZ | 6204ZZ | 14 | ||

| 90L | 311.5 | 175 | - | 150 | 15 | 56 | 9 | 50 | 40 | 168.5 | 24j6 | 7 | 4 | 8 | 6205ZZ | 6205ZZ | 21 | ||

| 100L | 366 | 200 | 212 | 180 | 4 | 63 | 12 | 60 | 45 | 193 | 28j6 | 7 | 4 | 8 | 6206ZZ | 6205ZZ | 31 | ||

| 112M | 381 | 230 | 242 | 180 | 4 | 70 | 12 | 60 | 45 | 200 | 28j6 | 7 | 4 | 8 | 6206ZZ | 6206ZZ | 42 | ||

| 132S | 450.5 | 256 | 268 | 180 | 4 | 89 | 12 | 80 | 63 | 239 | 38k6 | 8 | 5 | 10 | 6308ZZ | 6207ZZ | 60 | ||

| 132M | 488.5 | 256 | 268 | 4 | 89 | 12 | 80 | 63 | 258 | 38k6 | 8 | 5 | 10 | 6308ZZ | 6207ZZ | 69 | |||

| 160M | 575 | 310 | - | 254 | 4 | 108 | 14.5 | 110 | 90 | 323 | 42k6 | 8 | 5 | 12 | 6309ZZ | 6308ZZ | 100 | ||

| 160L | 619 | 310 | - | 298 | 4 | 108 | 14.5 | 110 | 90 | 345 | 42k6 | 8 | 5 | 12 | 6309ZZ | 6308ZZ | 120 | ||

| 180M | 644 | 335 | - | 285 | 4 | 121 | 14.5 | 110 | 90 | 351.5 | 48k6 | 9 | 5.5 | 14 | 6311ZZ | 6310ZZ | 150,155 | ||

| 180LD | 720 | 341 | - | 323 | 4 | 121 | 14.5 | 110 | 90 | 370.5 | 55m6 | 10 | 6 | 16 | 6312ZZ | 6311ZZ | 245 | ||

| 200LD | 780.5 | 390 | - | 361 | 4 | 133 | 18.5 | 140 | 110 | 425.5 | 60m6 | 11 | 7 | 18 | 6315ZZ | 6312ZZ | 300,325 | ||

| 225S | 857 | 428 | - | 342 | 4 | 149 | 18.5 | 140 | 110 | 432 | 65m6 | 11 | 7 | 18 | 6315ZZ | 6312ZZ | 380 | ||

*The vertical tolerance for the shaft center is °-₀.₅

Since outline drawings are shown by representative models, some appearances may silghtly differ depending on the frame number.

Make sure to inquire when requiring exact external dimensions, since the external dimensions may be partially modified due to the refinement process, etc.

For frame number 180 LD, the terminal box is on top of the motor, not side-mounted. (Differ from 180M.)