Contents Menu

SUPER LINE K SERIES SINGLE PHASE

SUPER LINE K SERIES SINGLE PHASE The variety of type of Single Phase Motor based on JIS (Japanese Industrial Standard) and IEC (International Electrotechnical Commission).

And being positively advanced under technological assistance contract with MITSUBISHI ELECTRIC JAPAN which have an experience for manufacturing motor since 1907.

Feature and Benefits

The variety of type of Single Phase Motor based on JIS (Japanese Industrial Standard) and IEC (International Electrotechnical Commission).

And being positively advanced under technological assistance contract with MITSUBISHI ELECTRIC JAPAN which have an experience for manufacturing motor since 1907.

- Top class of light weighting and down sizing

The best choice of employing steel frame and steel or aluminium bracket (excluding Sl-K Type) that enables light weighting and down sizing motor.

- High efficiency and high torque

Accumulated techniques and CAE (Computer Aided Engineering) analysis that we found steel frame pass through magnetic field then can manufacture high power and save energy of motor.

- Powerful and smooth speed

Due to high efficiency design focused on high acceleration torque and die-cast rotor of rather small moment of inertia enables smooth starting and stopping.

- Low vibration and low noise

Our highly technology equipment, the ample rigidity, precise machining of each part and exact balancing of electrical design which makes MEATH motor have low vibration and low noise.

- High reliability

Improve to highly reliable insulation system by using thermal class E, B, and F to be standard.

- Longer life

Based on selecting the proper bearing size and improving to have highly efficient cooling of bearing housing and steel frame which is greatly affect the longer bearing life.

- Best and reliable design of centrifugal switch

The best design of centrifugal switch from MITSUBISHI ELECTRIC JAPAN that can manufacture in our highly technology equipment which can be reliable.

Characteristics and Performance

| Item | SP-KR | SC-KR | SCL-KR | Sl-K | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Output (HP) | 1/4 | 1/3 | 1/2 | 1/4 | 1/3 | 1/2 | 1 | 1.5 | 2 | 3 | 5 | 7.5 | 10 | 1/2 | 1 | 1 3/4 |

| Frame No. | A71 | B71 | 80M | A71 | B71 | 80M | 90S | 90L | 100L | 112M | 132S | 132M | 132ML | 100 | 100 | 100 |

| No. of Poles | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Thermal Class | E | E | E | E | E | E | B | B | B | B | F | F | F | E | E | E |

| Power Supply | 1 Phase 220V 50Hz | |||||||||||||||

| Full Load Current (A) | 2.8 | 3.1 | 4.8 | 2.6 | 3.1 | 4.3 | 5.2 | 7.9 | 10.4 | 15.1 | 23 | 34 | 44.5 | 3.5 | 7.6 | 12 |

| Full Load Speed (r/min) | 1450 | 1440 | 1440 | 1450 | 1450 | 1430 | 1430 | 1440 | 1450 | 1450 | 1430 | 1450 | 1450 | 1455 | 1460 | 1450 |

| Starting Current (A) | 20 | 26.5 | 34 | 11 | 13.5 | 18.5 | 32 | 44 | 55 | 95 | 107 | 162 | 215 | 12.5 | 25 | 40 |

| Starting Torque (%) | 300 | 290 | 200 | 360 | 302 | 273 | 286 | 244 | 203 | 238 | 232 | 193 | 198 | 615 | 480 | 380 |

| Break Down Torque (%) | 310 | 270 | 293 | 280 | 262 | 390 | 250 | 290 | 239 | 260 | 174 | 195 | 187 | 478 | 290 | 250 |

| Power Supply | 1 Phase 220V 60Hz | |||||||||||||||

| Full Load Current (A) | 2.4 | 2.8 | 4.6 | 2.3 | 2.8 | 3.6 | 4.6 | 7.1 | 9.4 | 13.4 | 23 | 33.5 | 40 | 3.0 | 5.9 | 10.3 |

| Full Load Speed (r/min) | 1740 | 1730 | 1730 | 1740 | 1740 | 1720 | 1720 | 1720 | 1740 | 1740 | 1720 | 1700 | 1740 | 1750 | 1750 | 1740 |

| Starting Current (A) | 19.5 | 26 | 34 | 10.3 | 13.3 | 19.3 | 32 | 45 | 54 | 73 | 102 | 171 | 208 | 13.5 | 27 | 40 |

| Starting Torque (%) | 288 | 232 | 161 | 370 | 303 | 251 | 310 | 285 | 260 | 374 | 174 | 203 | 200 | 670 | 548 | 350 |

| Break Down Torque (%) | 299 | 227 | 251 | 283 | 229 | 327 | 265 | 225 | 245 | 202 | 165 | 210 | 170 | 435 | 265 | 227 |

| Net Weight (kg) | 6.6 | 7.5 | 11 | 6.8 | 7.6 | 11.4 | 15.2 | 18.6 | 23.4 | 32.8 | 45.8 | 60 | 68.2 | 26.4 | 32 | 36.6 |

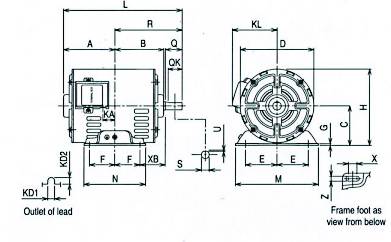

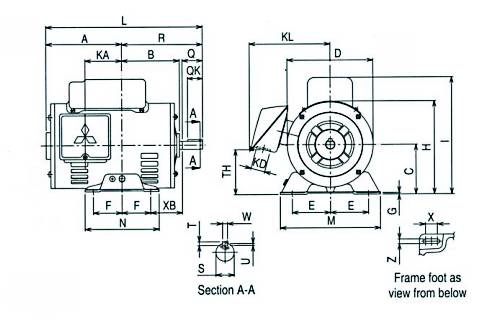

SP-KR SPLIT PHASE START TYPE

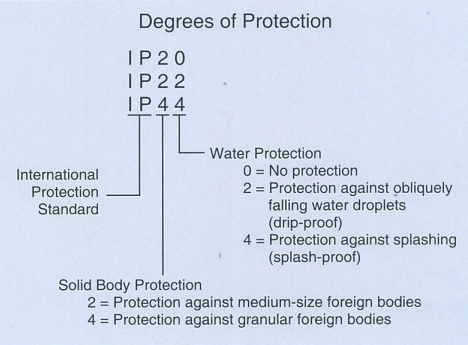

Open-Protected Type, IP 20 Degrees of Protection

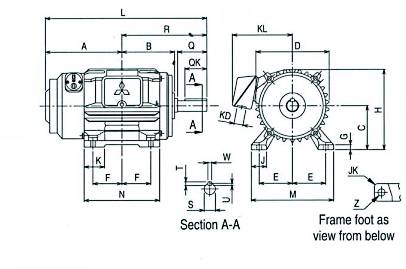

Dimensions(mm)

| Model | Frame No. | Output HP(kW) | Pole | Fig. | Motor | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C* | D | E | F | G | H | KA | KD1 | KD2 | KL | L | M | N | X | XB | Z | |||||

| SP-KR | A71 | 1/4(0.2) | 4 | 1 | 92 | 87 | 71 | 131.2 | 56 | 45 | 3.2 | 136.6 | 21.3 | 12 | 12 | 82 | 212 | 148 | 110 | 15 | 45 | 9 |

| B71 | 1/3(0.25) | 4 | 101 | 87 | 71 | 131.2 | 56 | 45 | 3.2 | 136.6 | 30.3 | 12 | 12 | 82 | 221 | 148 | 110 | 15 | 45 | 9 | ||

| 80M | 1/2(0.4) | 4 | 2 | 125 | 97 | 80 | 146.6 | 62.5 | 50 | 3.2 | 153.3 | 44.5 | 12 | 12 | 92 | 265 | 165 | 130 | 10 | 50 | 10 | |

* The perpendicular variation of tolerance for the shaft center is -0.5

| Model | Frame No. | Output HP(kW) | Pole | Fig. | Shaft End | Bering No. | Appoximate Weight (kg) | Appoximate Packing Dimensions (LxWxH) | Packing Weight (kg) | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Q | QK | R | S | T | U | W | Drive End | Opposite | ||||||||||||||||||

| SP-KR | A71 | 1/4(0.2) | 4 | 1 | 30 | 27 | 120 | 14 h6 | - | 1 | - | 6202ZZ | 6201ZZ | 6.6 | 245 x 200 x 184 | 7.0 | ||||||||||

| B71 | 1/3(0.25) | 4 | 30 | 27 | 120 | 14 h6 | - | 1 | - | 6202ZZ | 6201ZZ | 7.5 | 255 x 200 x 184 | 8.0 | ||||||||||||

| 80M | 1/2(0.4) | 4 | 2 | 40 | 28 | 140 | 16 j6 | 5 | 3 | 5 | 6203ZZ | 6202ZZ | 11 | 300 x 200 x 184 | 12 | |||||||||||

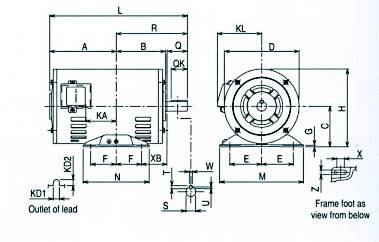

Dimensions(mm)

| Model | Frame No. | Output HP(kW) | Pole | Fig. | Motor | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C* | D | E | F | G | H | KA | KD1 | KD2 | KL | L | M | N | X | XB | TH | Z | |||||

| SC-KR | A71 | 1/4(0.2) | 4 | 3 | 92 | 87 | 71 | 131.2 | 56 | 45 | 3.2 | 136.6 | 21.3 | 12 | 12 | 82 | 212 | 148 | 110 | 15 | 45 | 170 | 9 |

| B71 | 1/3(0.25) | 4 | 101 | 87 | 71 | 131.2 | 56 | 45 | 3.2 | 136.6 | 30.3 | 12 | 12 | 82 | 221 | 148 | 110 | 15 | 45 | 167 | 9 | ||

| 80M | 1/2(0.4) | 4 | 4 | 125 | 97 | 80 | 146.6 | 62.5 | 50 | 3.2 | 153.3 | 44.5 | 12 | 12 | 92 | 265 | 165 | 130 | 10 | 50 | 173 | 10 | |

* The perpendicular variation of tolerance for the shaft center is -0.5

| Model | Frame No. | Output HP(kW) | Pole | Fig. | Shaft End | Bering No. | Appoximate Weight (kg) | Appoximate Packing Dimensions (LxWxH) | Packing Weight (kg) | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Q | QK | R | S | T | U | W | Drive End | Opposite | ||||||||||||||||||

| SP-KR | A71 | 1/4(0.2) | 4 | 3 | 30 | 27 | 120 | 14 h6 | - | 1 | - | 6202ZZ | 6201ZZ | 6.8 | 245 x 200 x 184 | 7.5 | ||||||||||

| B71 | 1/3(0.25) | 4 | 30 | 27 | 120 | 14 h6 | - | 1 | - | 6202ZZ | 6201ZZ | 7.6 | 255 x 200 x 184 | 8.2 | ||||||||||||

| 80M | 1/2(0.4) | 4 | 4 | 40 | 28 | 140 | 16 j6 | 5 | 3 | 5 | 6203ZZ | 6202ZZ | 11.4 | 300 x 200 x 184 | 12 | |||||||||||

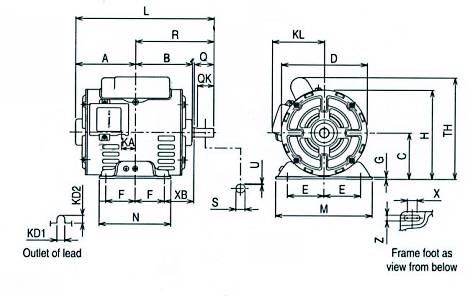

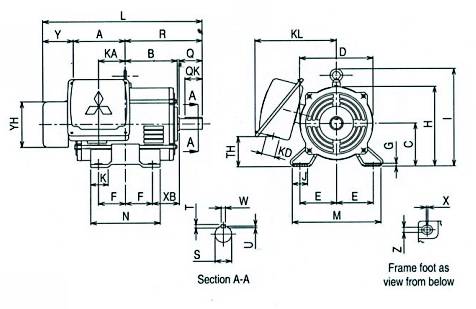

SCL-KR CAPACITOR START AND RUN TYPE

Drip-proof Type, IP 22 Degrees of protection

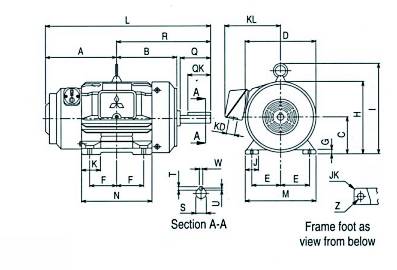

Dimensions(mm)

| Model | Frame No. | Output HP(kW) | Pole | Fig. | Motor | |||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C* | D | E | F | G | H | I | J | K | KA | KD | KL | L | M | N | XB | TH | Y | YH | X | Z | ||||||

| SCL-KR | 90S | 1(0.75) | 4 | 5 | 132 | 103 | 90 | 165.7 | 70 | 50 | 3.2 | 173 | 220 | - | - | 68 | 27 | 157 | 278 | 175 | 125 | 56 | 81 | - | - | 10 | 10 | |

| 90L | 1.5(1.1) | 4 | 120 | 115 | 90 | 165.7 | 70 | 62.5 | 4 | 173 | 220 | - | - | 55 | 27 | 157 | 313 | 175 | 150 | 56 | 81 | - | - | 15 | 9 | |||

| 100L | 2(1-5) | 4 | 6 | 118 | 128 | 100 | 168 | 80 | 70 | 6.5 | 184 | - | 40 | 45 | 65 | 35 | 201 | 400 | 200 | 180 | 63 | 64 | 89 | 118 | 4 | 12 | ||

| 112M | 3(2.2) | 4 | 125 | 135 | 112 | 190 | 95 | 70 | 6.5 | 207 | 254 | 40 | 45 | 69 | 35 | 211 | 414 | 230 | 180 | 70 | 79 | 89 | 118 | 4 | 12 | |||

| 132S | 5(3.7) | 4 | 7 | 223 | 152 | 132 | 266 | 108 | 70 | 6.5 | 242 | 289 | 40 | 45 | 75 | 27 | 215 | 462 | 256 | 180 | 89 | 117 | - | - | 4 | 12 | ||

| 132M | 7.5(5.5) | 4 | 242 | 171 | 132 | 266 | 108 | 89 | 6.5 | 242 | 289 | 40 | 45 | 94 | 35 | 240 | 500 | 256 | 218 | 89 | 106 | - | - | 4 | 12 | |||

| 132ML | 10(7.5) | 4 | 270 | 171 | 132 | 266 | 108 | 89 | 6.5 | 242 | 289 | 40 | 45 | 122 | 35 | 240 | 528 | 256 | 218 | 89 | 106 | - | - | 4 | 12 | |||

* The perpendicular variation of tolerance for the shaft center is -0.5

| Model | Frame No. | Output HP(kW) | Pole | Fig. | Shaft End | Bering No. | Appoximate Weight (kg) | Appoximate Packing Dimensions (LxWxH) | Packing Weight (kg) | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Q | QK | R | S | T | U | W | Drive End | Opposite | |||||||||||||||||||||

| SCL-KR | 90S | 1(0.75) | 4 | 5 | 40 | 28 | 146 | 19 j6 | 6 | 3.5 | 6 | 6204ZZ | 6202ZZ | 15 | 368 x 280 x 250 | 16 | |||||||||||||

| 90L | 1.5(1.1) | 4 | 50 | 40 | 169 | 24 j6 | 7 | 4 | 8 | 6205ZZ | 6203ZZ | 18.6 | 390 x 280 x 250 | 18.2 | |||||||||||||||

| 100L | 2(1-5) | 4 | 6 | 60 | 45 | 193 | 28 j6 | 7 | 4 | 8 | 6206ZZ | 6205ZZ | 24.5 | 437 x 355 x 300 | 25.4 | ||||||||||||||

| 112M | 3(2.2) | 4 | 60 | 45 | 200 | 28 j6 | 7 | 4 | 8 | 6207ZZ | 6206ZZ | 32.8 | 504 x 411 x 327 | 39 | |||||||||||||||

| 132S | 5(3.7) | 4 | 7 | 80 | 63 | 239 | 38 k6 | 8 | 5 | 10 | 6308ZZ | 6207ZZ | 45.8 | 552 x 438 x 359 | 53 | ||||||||||||||

| 132M | 7.5(5.5) | 4 | 80 | 63 | 258 | 38 k6 | 8 | 5 | 10 | 6308ZZ | 6207ZZ | 60 | 602 x 475 x 369 | 68 | |||||||||||||||

| 132ML | 10(7.5) | 4 | 80 | 63 | 258 | 38 k6 | 8 | 5 | 10 | 6308ZZ | 6207ZZ | 68.2 | 630 x 475 x 369 | 76 | |||||||||||||||

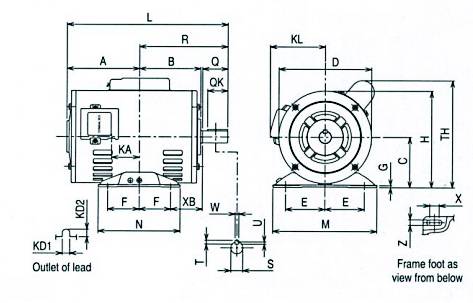

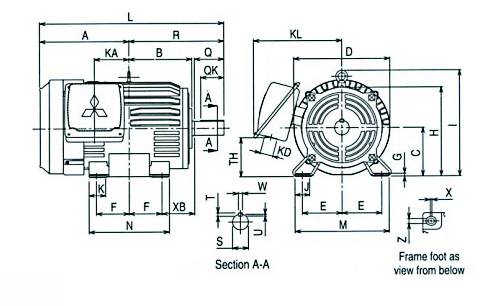

Dimensions(mm)

| Model | Frame No. | Output HP(kW) | Pole | Fig. | Motor | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C* | D | E | F | G | H | I | J | JK | K | KD | KL | L | M | N | Z | |||||

| SI-K | 100 | 1/2(0.4) | 4 | 8 | 170.5 | 128 | 100 | 208 | 80 | 70 | 12 | 204 | - | 40 | 3 | 40 | 27 | 161 | 343.5 | 200 | 175 | 12 |

| 100 | 1 (0.75) | 4 | 9 | 170.5 | 168.5 | 100 | 212 | 80 | 70 | 12 | 206 | 237.5 | 40 | 3 | 40 | 27 | 161 | 383.5 | 200 | 175 | 12 | |

| 100 | 1 3/4 (1.3) | 4 | 185.5 | 168.5 | 100 | 212 | 80 | 70 | 12 | 206 | 237.5 | 40 | 3 | 40 | 27 | 161 | 398.5 | 200 | 175 | 12 | ||

* The perpendicular variation of tolerance for the shaft center is -0.5

| Model | Frame No. |

Output HP(kW) |

Pole | Fig. | Shaft End | Bering No. | Appoximate Weight (kg) |

Appoximate Packing Dimensions (LxWxH) |

Packing Weight (kg) |

||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Q | QK | R | S | T | U | W | Drive End | Opposite | |||||||||||||||||

| SI-K | 100 | 1/2(0.4) | 4 | 8 | 40 | 28 | 173 | 16 j6 | 5 | 3 | 5 | 6205ZZ | 6203ZZ | 26.4 | 395 x 309 x 258 | 28.2 | |||||||||

| 100 | 1 (0.75) | 4 | 9 | 40 | 36 | 213 | 22 j6 | 7 | 4 | 8 | 6205ZZ | 6203ZZ | 32.0 | 424 x 309 x 258 | 34 | ||||||||||

| 100 | 1 3/4 (1.3) | 4 | 40 | 36 | 213 | 24 j6 | 7 | 4 | 8 | 6206ZZ | 6204ZZ | 36.6 | 522 x 372 x 320 | 43.6 | |||||||||||

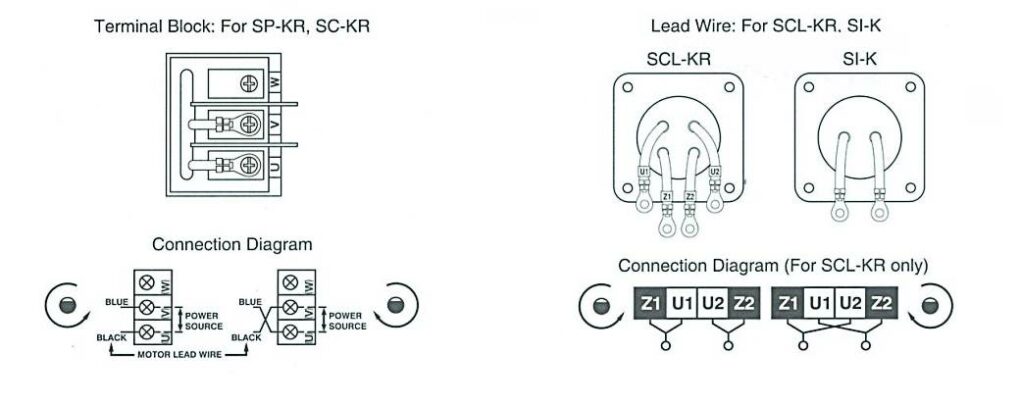

Standard Specifications

| Item | Specifications | ||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Voltage and Frequency | 220-230V 50Hz, 220V 60Hz | ||||||||||||||||||||||||||||||||

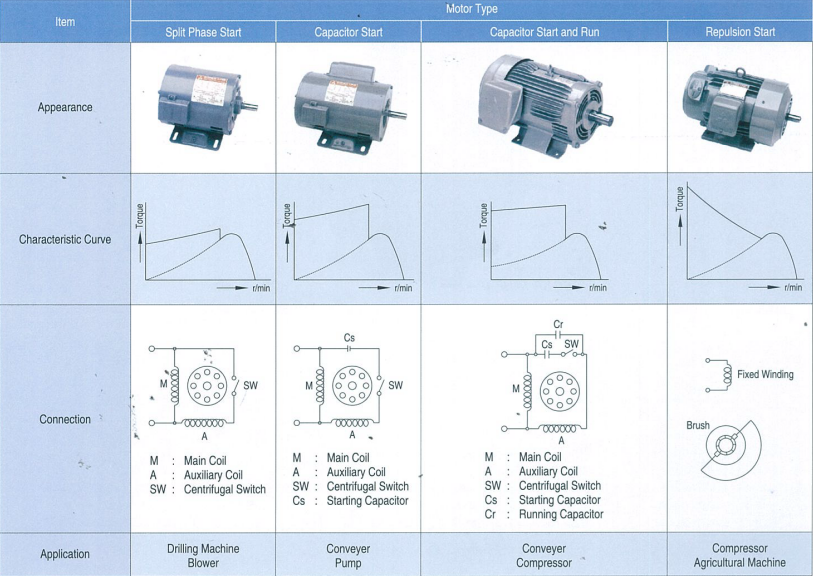

| Starting Method, Enclosure Construction and Degrees of Protection |

|

||||||||||||||||||||||||||||||||

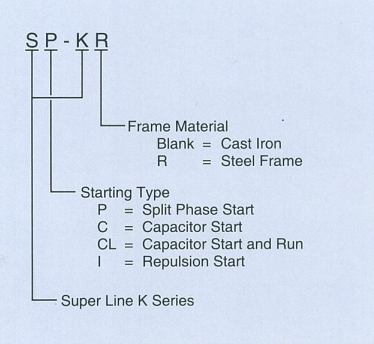

| Frame Material | SP-KR, SC-KR, SCL-KR : Steel Plate | ||||||||||||||||||||||||||||||||

| SI-K : Cast Iron | |||||||||||||||||||||||||||||||||

| Thermal Class | SP-KR, SC-KR, SI-K : Class E | ||||||||||||||||||||||||||||||||

| SCL-KR 90S-112M : Class B | |||||||||||||||||||||||||||||||||

| 132S ~ 132ML : Class F | |||||||||||||||||||||||||||||||||

| Circumstance Condition |

Ambient Temperature |

-20 ~ +40°C | |||||||||||||||||||||||||||||||

| Ambient Humidity |

85% RH or less (for Opened Protected & Drip-proof Structure) 95% RH or less (for Totally Enclosed Structure) |

||||||||||||||||||||||||||||||||

| Altitude | Less than 1,000m above sea level | ||||||||||||||||||||||||||||||||

| Environment | No bursting / erosive gas or vapor | ||||||||||||||||||||||||||||||||

| Coating | Colour | Munsell N5.5 (Gray) | |||||||||||||||||||||||||||||||

| Conformed Standard | IEC 60034-1 & JIS C 4203 (for SP-KR, SC-KR), JEC-2137-2000 (for SCL-KR, Sl-K) | ||||||||||||||||||||||||||||||||